Cold rolled alloy steel strip has high requirements for production technology. In steelmaking, hot rolling, cold rolling, heat treatment and finishing of the various processes are more difficult to produce, its full process of consistent manufacturing technology, especially hot rolling control and heat treatment are the core.

Volda adopts the mode of hot-rolled blanks from large steel companies such as BaoSteel, Shougang Steel, utilizing proprietary mills to process cold rolling and annealing to meet the requirements of dimensional accuracy and excellent surface quality.

Cold Rolled Alloy Steel Strip - Hardened and Tempered

• Chemical Composition (%) - Nickel Chromium Steel

| JIS | C | Si | Mn | P | S | Cu | Ni | Cr |

| SNC631M | 0.27-0.35 | 0.15-0.35 | 0.35-0.65 | 0.030 | 0.030 | 0.30 | 2.50-3.00 | 0.60-1.00 |

| SNC836M | 0.32-0.40 | 0.15-0.35 | 0.35-0.65 | 0.030 | 0.030 | 0.30 | 3.00-3.50 | 0.60-1.00 |

| SNC415M | 0.12-0.18 | 0.15-0.35 | 0.35-0.65 | 0.030 | 0.030 | 0.30 | 2.00-2.50 | 0.20-0.50 |

| SNC815M | 0.12-0.18 | 0.15-0.35 | 0.35-0.65 | 0.030 | 0.030 | 0.30 | 3.00-3.50 | 0.60-1.00 |

• Thickness Tolerance (mm)

Several different grades of thickness allowance― A(standard) and S, SS, and SSS(special)― are available. The thickness is

measured arbitrarily at more than 10 mm from the edge of the steel. When the width is 20 mm or less, the steel is measured in the center portion.

| Grade | A | S | SS | SSS |

| Largura | Less than 450 | Less than 450 | Less than 400 | Less than 200 |

| Thickness | ||||

| 0.10-0.15 | ±0.010 | ±0.008 | ±0.007 | ±0.006 |

| 0.15-0.25 | ±0.015 | ±0.010 | ±0.008 | ±0.007 |

| 0.25-0.40 | ±0.020 | ±0.015 | ±0.010 | ±0.008 |

| 0.40-0.60 | ±0.025 | ±0.020 | ±0.015 | ±0.010 |

| 0.60-0.90 | ±0.030 | ±0.025 | ±0.020 | ±0.015 |

| 0.90-1.20 | ±0.040 | ±0.030 | ±0.025 | ±0.020 |

| 1.20-1.60 | ±0.050 | ±0.040 | ±0.030 | ±0.025 |

| 1.60-2.10 | ±0.055 | ±0.050 | ±0.040 | ±0.030 |

| 2.10-2.60 | ±0.060 | ±0.055 | ±0.050 | ±0.040 |

| 2.60-3.25 | ±0.065 | ±0.060 | ±0.050 | ±0.045 |

| 3.25-4.00 | ±0.080 | ±0.070 | ±0.060 | ±0.050 |

| 4.00-5.00 | ±0.090 | ±0.080 | ±0.070 | --- |

• Width Tolerance (mm)

| Grade | A | S | ||

| Largura | Less than 200 | Less than 450 | Less than 200 | Less than 450 |

| Thickness | ||||

| <0.60 | ±0.15 | ±0.25 | ±0.10 | ±0.20 |

| 0.60-1.20 | ±0.20 | ±0.30 | ±0.15 | ±0.25 |

| 1.20-3.25 | ±0.25 | ±0.40 | ±0.20 | ±0.35 |

| 3.25-4.00 | ±0.25 | ±0.40 | ±0.20 | ±0.35 |

| 4.00-5.00 | ±0.40 | ±0.55 | ±0.35 | ±0.50 |

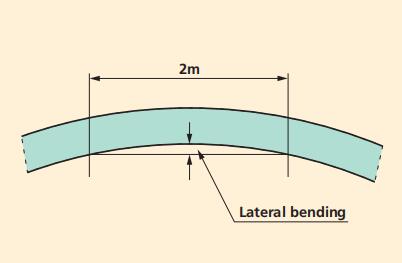

• Lateral Bending Tolearance (mm)

| Grade | A | S | SS |

| Largura | |||

| 10-20 | 20 | 15 | 12 |

| 20-40 | 15 | 10 | 8 |

| 40-80 | 8 | 6 | 4 |

| 80-450 | 4 | 3 | - |

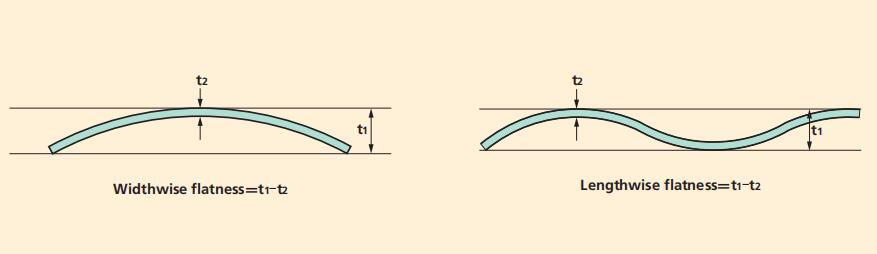

• Flatness Tolerance (mm)

| Tolerance | Thickness | |||||

| ≤0.60 | 0.60-1.20 | 1.20-3.20 | 3.20-5.00 | |||

| ≤200 | Annealed | Widthwise | 1.0 | 1.0 | 1.5 | 2.0 |

| Lengthwise | 2.0 | 3.0 | 3.0 | 5.0 | ||

| Hard-drawn | Widthwise | 1.0 | 1.5 | 1.5 | 2.5 | |

| Lengthwise | 3.0 | 4.0 | 4.0 | 6.0 | ||

| 200-450 | Annealed | Widthwise | 1.5 | 2.0 | 2.5 | 3.0 |

| Lengthwise | 4.0 | 5.0 | 5.0 | 7.0 | ||

| Hard-drawn | Widthwise | 1.5 | 2.0 | 3.0 | 4.0 | |

| Lengthwise | 6.0 | 7.0 | 7.0 | 9.0 | ||

• Hardness (HV)

| Standard | Type of Steel | Annealing Hardness | Deep-Drawing Hardness | |

| Standard | Special | |||

| JIS | SNCM220M | 170 | 160 | --- |

| SNCM240 | 180 | 160 | --- | |

| SCr415 | 170 | 150 | --- | |

| SCr420 | 170 | 150 | --- | |

| SCM435M | 180 | 160 | 200-260 | |

| SCM440M | 180 | 160 | 200-260 | |

| SCM415M | 160 | 150 | --- | |

| SMn443 | 180 | 160 | 200-280 | |

| SAE | SAE1541 | 170 | 150 | 200-280 |

| SAE1552 | 180 | 160 | 200-280 | |

| SAE4130 | 180 | 160 | --- | |

| SAE8615 | 170 | 150 | --- | |

• Heat Treatment

| Type of Steel | Oil Hardening | |

| Temperature (°C) | Hardness (HRC) | |

| SNCM240 | 820-870 | 53 |

| SNCM21M | 850-900 | 35 |

| SAE8615 | 850-900 | 35 |

| SCr415 | 850-900 | 33 |

| SCr420 | 850-900 | 35 |

| SCM435M | 830-880 | 48 |

| SCM440M | 830-880 | 51 |

| SCM415M | 850-900 | 35 |

| SAE4130 | 830-880 | 45 |

| SAE1541 | 830-880 | 54 |

| SAE1552 | 810-880 | 54 |

• Finish

Aside from ordinary annealing and hard-drawn finishes, Volda also implements PPC, PT, and other

finishes aimed at speeding up hardening and conserving heat. Cold-rolled special steel strip is available in the following finishes.

| Stage | Symbol | Condition |

| Annealing | A | Annealing is implemented after cold rolling |

| Skinpass | S | Annealing and thermal refining are implemented after cold rolling |

| Deep drawing | C | Cold rolling is implemented |

| Patenting | PT | Patenting treatment and fixed cold rolling are implemented |

| PPC | PC | Spheroidal carbide is refined |

• Applications

Automobile Seat Reclining Parts

Link Chain

Seat Adjuster

Shock Absorber

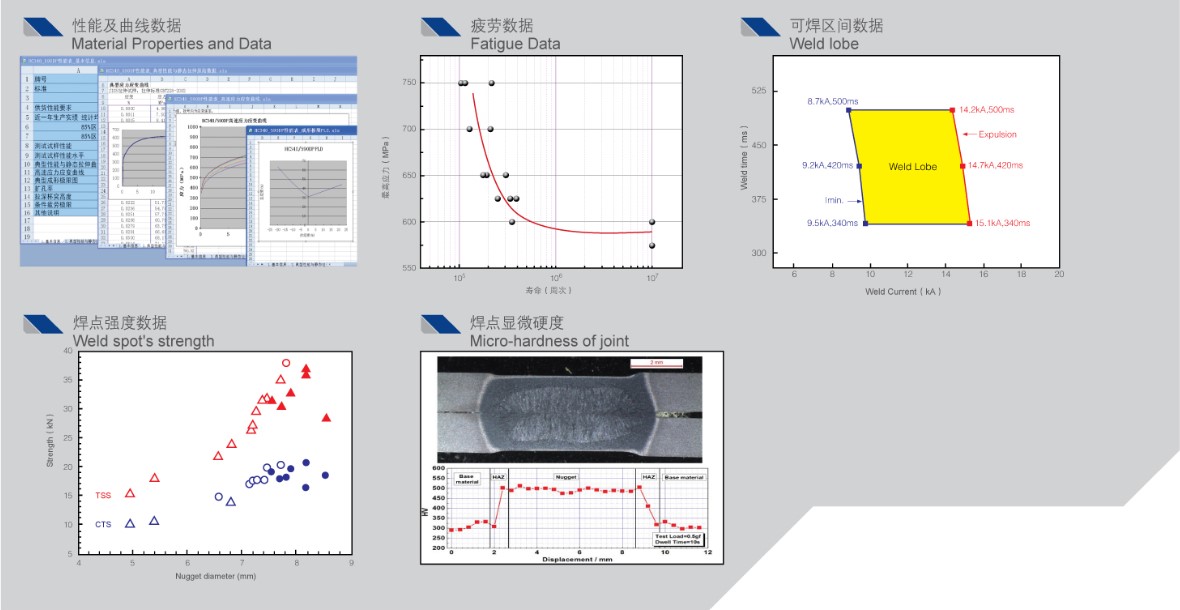

We have processing and forming simulation and analysis technology for cold rolled special steel strips and can carry out heat treatment, welding, stamping, roller pressure, rotary pressure, thermoforming and hydroforming and other process simulation and simulation analysis.

We also can provide users with high strength steel forming technical support and mold improvement support as well as 50kg-500kg sample testing with advanced technologies from steelmaking - hot rolling - pickling - cold rolling - annealing and other processes.